VIZZIO Technologies, POLYTRON.AI, and Foxconn Industrial Internet (Fii), have once again joined forces to launch Vietnam’s first World Economic Forum (WEF) Lighthouse Factory. This new facility, located at Fii’s Bắc Giang plant in Vietnam, is a beacon of smart manufacturing, incorporating cutting-edge AI, real-time analytics, and advanced real-time 3D digital twin technology to transform industrial operations.

This new Lighthouse Factory highlights Fii’s leadership in adopting Industry 4.0 innovations, optimising production, enhancing sustainability, pioneering highly efficient manufacturing models, and fortifying digital transformation, positioning them as leaders in both innovation and responsible production.

Leveraging VIZZIO’s expertise in large-scale 3D city mapping and visualisation along with POLYTRON’s cutting-edge AI-driven 360-degree vision security solutions, this collaboration represents a transformative step for Fii and the entire manufacturing industry. The integration of these advanced technologies not only enhances security and operational efficiency but also positions Fii at the forefront of smart manufacturing innovations. This partnership sets a new benchmark for digital transformation in industrial environments, driving significant advancements in automation, surveillance, and intelligent infrastructure for factories of the future.

Leading the Future of Smart Manufacturing

Foxconn Industrial Internet (Fii) is at the forefront of the global electronics manufacturing industry, integrating smart technologies to improve operational efficiency, sustainability, and security. Fii’s latest WEF Lighthouse Factory certification demonstrates its commitment to setting a global standard for manufacturing excellence by harnessing cutting-edge technologies like 3D mapping and VISION based AI autonomous virtual patrol systems.

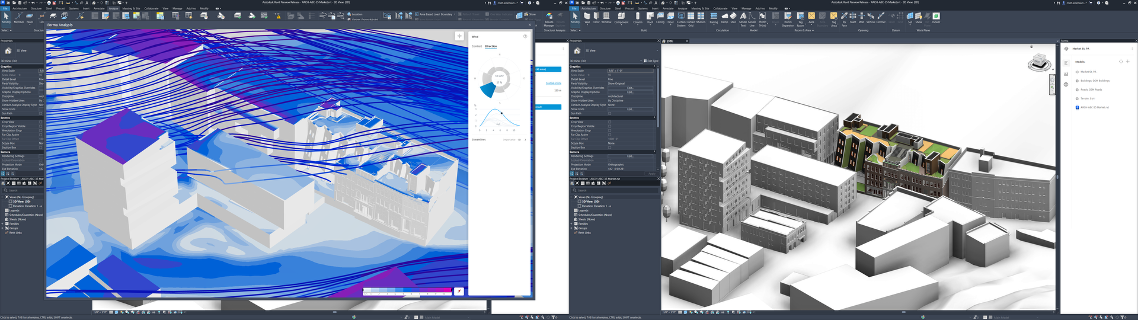

By leveraging innovative technologies, such as 3D city mapping powered by a multi-modal AI engine, (Fii) is pushing the boundaries of industrial digitisation. This AI engine segments and interprets satellite images, street views, videos, and point clouds, creating dimensionally accurate, geo-specific, and geo-typical parametric hyper-photorealistic 3D digital twins. In addition, Fii deploys POLYTRON’s patented AI 360 vision-based autonomous patrol system, which is equipped with 360-degree security cameras to enhance surveillance capabilities.

Fii’s groundbreaking efforts have earned it the World Economic Forum (WEF) Lighthouse Factory certification for its first factory facility in Vietnam, underscoring its dedication to setting global benchmarks for manufacturing excellence. This prestigious recognition highlights Fii’s focus on incorporating advanced technologies to revolutionise its production processes, fostering an ecosystem that is not only sustainable and secure but also intelligent and future-ready. The certification further emphasises Fii’s leadership in promoting a tech-driven industrial model, setting new standards for the global manufacturing sector.

Creating the Digital Twin of Bắc Giang

“We are dedicated to building the factories of the future – ones that are not only highly automated and connected but also secure and sustainable,” said Zongchang Liu, Chief Data Officer of Fii.

“Our latest Lighthouse Factory demonstrates how technologies such as real-world digital twins and AI-driven 360-degree autonomous security systems can be seamlessly integrated to create a real-time 3D scene that is accessible via any device, allowing users to experience being ‘physically there’ without actually being on-site. This innovation enables our security and manufacturing teams to utilise a 24/7 autonomous patrol system powered by a multi-modal AI agent that comprehends everything it sees and promptly reports any anomalies. This advanced integration not only enhances the security and safety within the factory but also boosts the efficiency and sustainability of the entire manufacturing process.”

By seamlessly integrating multi-modal AI agents, unique POLYTRON’s 360 security camera, real-time live 3D Scene, and city-scale digital twins, Fii is pioneering a new era of smart factories that combine security with operational efficiency to build a truly future-ready manufacturing ecosystem. This sophisticated blend of technologies enables real-time monitoring, predictive maintenance, and autonomous decision-making processes, ensuring that safety and productivity are not just enhanced but fully optimised.