ABB has expanded its NeoGear switchgear portfolio to deliver impressive safety improvements, optimised performance and digital connectivity

Building on the success of its proven NeoGear technology, ABB has further developed NeoGear, the safest low-voltage switchgear on the market for operators and maintenance engineers. Its revolutionary design eliminates hazardous exposure to live parts, uses 92 percent fewer busbar components than traditional switchgear and with 90 percent fewer electrical joints improves switchgear availability. The arc ignition protected zone keeps maintenance personnel safer when performing routine works and repairs, while also reducing the risk of arcs caused by mechanical failures, one of the most serious safety risks that switchgear operators encounter.

With increased attention on sustainability, investors and business partners are now focusing on ESG with ASEAN aiming to reduce energy intensity by 30% come 2025. Now available globally, NeoGear switchgear offers a reduced physical footprint by up to 25 percent compared to equivalent switchgear technologies. Within this compact footprint, it also achieves energy efficiency of up to 20 percent due to reduced heat dissipation.

The recently introduced 4-pole version, as well as the upcoming 690 V version, make NeoGear a very attractive solution for numerous market segments and industries, including utilities, food & beverage and infrastructure. NeoGear is also ideal for data centres, infrastructure and light industries where the highest safety standards and reliability are essential and where the reduced physical footprint and weight reduction of the switchgear are key benefits.

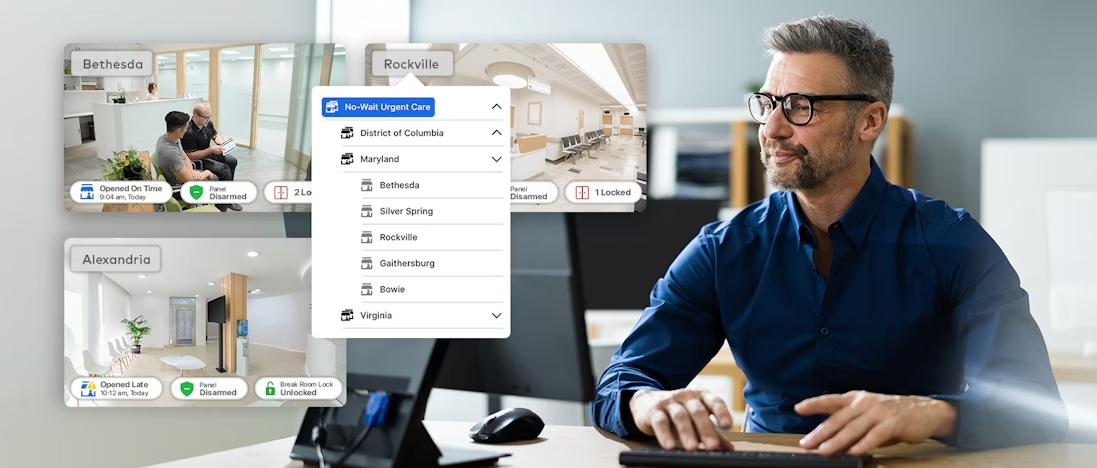

As well as improved safety, class-leading sustainability credentials and unrivalled performance, the enhanced solution builds on ABB’s proven NeoGear platform with the latest connectivity capabilities for data analytics and data communication, making it the ideal low-voltage switchgear option for facilities working towards achieving Industry 4.0 standards. The new digital capabilities deliver up to overall 30 percent lower operational costs thanks to more efficient condition monitoring – making it a revolutionary step forward for sustainable switchgear.

Scott Douglas, Low Voltage Switchgear Product Marketing Manager for ABB Electrification Asia explains: “The industries we serve are constantly evolving in line with key market drivers like digitalization, safety and reduction of environmental impact. ABB’s innovative solutions provide our customers in Asia with the right capabilities to grow business while not compromising on energy efficiency to meet their sustainability goals”.

“The advancements made to our NeoGear low-voltage switchgear showcases our commitment to product evolution at ABB, where we ensure that beyond improving operational safety and sustainability, having an integrated smart functionality is also crucial to complementing any digitalisation strategy.”

The expanded digital capabilities of NeoGear include real-time condition monitoring and predictive maintenance, remote assistance, fault and solutions diagnostics and data analytics for Industry 4.0. Furthermore, ABB AbilityTM Condition Monitoring for Electrical Systems (CMES) is also included to help customers gain additional operational efficiencies of up to 30 percent and harness unprecedented flexibility in their operations.