2014 Pritzker Prize Laureate Revealed

Shigeru Ban

“Shigeru Ban is a tireless architect whose work exudes optimism. Where others may see insurmountable challenges, Ban sees a call to action. Where others might take a tested path, he sees the opportunity to innovate. He is a committed teacher who is not only a role model for younger generation, but also an inspiration.” — Pritzker Jury 2014

Shigeru Ban, a 56 year old architect, has been announced as the 2014 Laureate of the Pritzker Architecture Prize. Established by the Pritzker family of Chicago in 1979, the prestigious award is widely regarded as “the Nobel Prize” in the architecture profession.

Ban is the seventh Japanese architect to become a Pritzker Laureate since– following Kenzo Tange in 1987, Fumihiko Maki in 1993, Tadao Ando in 1995, the team of Kazuyo Sejima and Ryue Nishizawa in 2010, and Toyo Ito last year.

According to the jury, the Pritzker Prize recognizes architects who both display “excellence in built work and who make a significant and consistent contribution to humanity.” Shigeru Ban, whose approach is as innovative as it is humanitarian, “reflects this spirit of the prize to the fullest.”

“He is a force of nature,” said the jury chairman, Lord Palumbo, “which is entirely appropriate in the light of his voluntary work for the homeless and dispossessed in areas devastated by natural disasters.”

“Receiving this prize is a great honour, and with it, I must be careful,” said Ban, who splits his time between offices in Tokyo, Paris and New York. “I must continue to listen to the people I work for, in my private residential commissions and in my disaster relief work. I see this prize as encouragement for me to keep doing what I am doing – not to change what I am doing, but to grow,” commented Ban on receiving the award.

A little of Ban’s background and his works

As a boy, Shigeru Ban observed traditional Japanese carpenters working at his parents’ house and to him their tools, the construction, and the smells of wood were magic. He would save cast aside pieces of wood and build small models with them. He wanted to become a carpenter. But at age eleven, his teacher asked the class to design a simple house and Ban’s was displayed in the school as the best. Since then, to be an architect was his dream.

Ban began his career in the office of Arata Isozaka, after being educated in America at the Southern California Institute of Architecture, and then New York’s Cooper Union School of Architecture.

He founded his own Tokyo practice in 1985 with little experience and went on to complete a number of residential projects in Japan such as Three Walls (1988), Curtain Wall House (1995) and Naked House (2000).

Curtain Wall House – Tokyo, Japan, 1995

Naked House – Saitama, Japan, 2000

In all parts of his practice, Ban finds a wide variety of design solutions, often based around structure, materials, view, natural ventilation and light, and a drive to make comfortable places for the people who use them. From private residences and corporate headquarters, to museums, concert halls and other civic buildings, Ban is known for the originality, economy, and ingeniousness of his works, which do not rely on today’s common high-tech solutions.

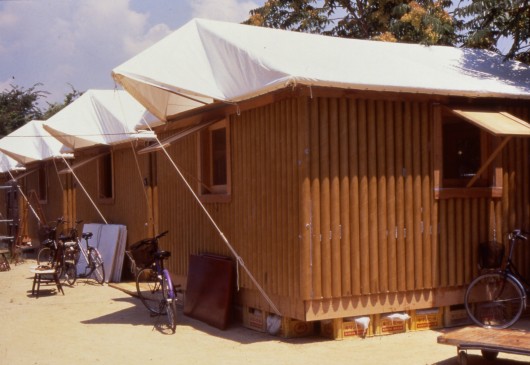

His first designs for paper-tube structures were used to provide temporary homes for Vietnamese refugees after the Kobe earthquake in 1995.

“When you finish a roll of tracing paper or fax paper, there are always paper tubes left over,” he said. “They were so strong and so nice, so I kept them. Then I went to the factory where they made them, and I saw they could make any length and any diameter.” Paper and cardboard have long been part of an architect’s toolbox for drawings and models of buildings, but for Japanese architect Shigeru Ban they are good enough to make the real thing.

Paper Log Houses – Kobe, Japan, 1995

In 1995, he founded a non-governmental organization called Voluntary Architects’ Network (VAN).With VAN, he has tackled disaster relief in Turkey, India, China and Haiti. Since then the architect has travelled to sites of natural and man-made disasters around the world to develop low-cost, recyclable shelters for affected communities.

His most recent disaster-relief project involved erecting a magnificent cardboard cathedral after the earthquake in Christchurch, New Zealand, resulting in an elegant A-frame next to the ruins of George Gilbert Scott’s stone building.

Cardboard Cathedral – Christchurch, New Zealand, 2013

Cardboard Cathedral Interior