New Green and Gracious Builder Scheme for Small and Medium Construction Firms

– Customised Green and Gracious Builder Scheme launched for small and medium builders

– Green and Gracious Builder Scheme Version 2 sees increased weightage for gracious best practices

– 19 firms to receive Green and Gracious Builder Award at the 2014 BCA Awards

Building and Construction Authority (BCA) has introduced a Green and Gracious Builder Scheme (GGBS) for Small and Medium Construction Firms (SMC) to encourage wider adoption of environmentally friendly and gracious practices among builders. Adapted from the Green and Gracious Builder Scheme, the GGBS (SMC) is a voluntary scheme tailored for builders who work on smaller projects. It places greater emphasis on operational and gracious practices that can be easily adopted by smaller builders.

BCA has also released an updated version of the Green and Gracious Builder Scheme. The revised scheme focuses on gracious building practices that help to minimise the impact on site and surroundings, such as improved accessibility, enhanced public safety and better noise and vibration control. In addition, manpower management practices have also been revised to emphasise employee engagement, staff welfare, retention and training.The overall weightage for Gracious Practices has been increased from 40 percent to 50 percent

These announcements come just ahead of the BCA Awards scheduled on 22 May 2014, where 19 builders will be conferred the Green and Gracious Builder Award. Five companies have successfully achieved the top ‘Star’ rating, with another eight companies receiving the ‘Excellent’ award. The remaining companies will receive the ‘Merit’ award. Of the 19 companies awarded this year, 12 builders will be receiving the award for the first time.

“Given high visibility and impact of construction works in Singapore, it is important for builders to go green and adopt ‘friendlier’ construction practices. We hope to reduce inconvenience and disturbance of noise, dust and accessibility for those living in the vicinity, as well as members of the public. It is heartening to see more green and gracious builders participate in this scheme every year, and how they have found innovative ways to build responsibly. With the new scheme for SMCs, we hope to inspire smaller builders that they too, can take simple steps to be the change agent contributing to the environment and the community-at-large,” said Dr John Keung, CEO of BCA.

Green and Gracious Builder Award Winners 2014

In line with the increased focus on Gracious Practices, this year’s Green and Gracious award winners have not only come up with innovative ways to engage employees but also redesigned their work processes with a green and gracious mind set right from the start.

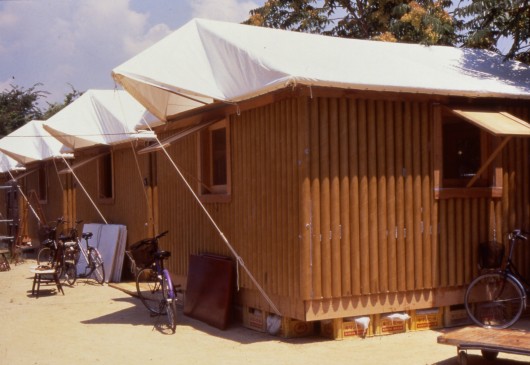

This year’s ‘Star’ award winner, Straits Construction Singapore Pte Ltd, has truly gone the extra mile to improve employee welfare. At its residential project, Kovan Regency, the company used excess construction materials to build recreational facilities for its workers. It has built a multi-purpose court, table tennis table, and gym equipment with pre-fabricated concrete planks, timber materials and surplus recycled concrete respectively. The project site even boasts a vegetable planting patch, which is collectively cared for by the workers. To minimise dust and noise for neighbours in the estate, the builder planted bamboo trees at the borders of the site to act as natural barriers, creating a more conducive worksite and living environment for the workers, as well as the community in the vicinity.

Gym facilities made out of recycled materials

Multipurpose court made out of precast planks constructed with concrete

Recycling bins made out of recycled construction material

Community vegetable patch tended by the workers

Potted plants located around the worksite to create a more pleasant environment

Table tennis table made out of recycled timber materials and reinforcement bars.

Singapore Piling and Civil Engineering Pte Ltd and Singa Development Pte Ltd are the first two companies to be assessed and awarded under the revised Green and Gracious Builder Scheme. Both builders have been given the ‘Star’ award for their use of advanced technology and innovative processes to improve productivity, conserve materials and enhance public safety.

For its Galaxis project, Singapore Piling and Civil Engineering Pte Ltd adopted a top-down construction method, where it built the basement levels and upper levels simultaneously. This not only improves productivity, but also helps to reduce the noise and dust generated during the construction process by having the upper levels shield the basement excavation work. In addition, the company designed its own unique underground support structure (One Layer Earth Retaining Stabilisation Structure (ERSS) Strut system) to help speed up basement construction and reduce vibration, noise and dust pollution.

Proving that smaller builders can also achieve green and gracious practices is Pal-Link Construction Pte Ltd. A Grade C1 “General Building” BCA registered contractor, Pal-Link has been awarded ‘Merit’ for its approach to piling which reduced the number of piles used. This helped to reduce noise pollution at its Millage Condominium site. To further reduce noise and dust pollution, the company also replaced the temporary retaining wall with diaphragm wall which also acts as a permanent structure and eliminates the need for hacking.

About GGBS and GGBA

First launched in February 2009, BCA’s Green and Gracious Builder Scheme and Green and Gracious Builder Award aims to raise the environmental consciousness and professionalism of builders. The award acts as a benchmark of a builder’s corporate social responsibility to the environment and the general public, and sets standards for green and gracious practices that builders can implement to address environmental concerns and mitigate possible inconveniences to the public caused by construction works. Both the revised Green and Gracious Builder Scheme and GGBS (SMC) scheme were developed in close consultation with Singapore Contractors Association Limited (SCAL) and other builders. To date, a total of 74 builders have been certified under the Green and Gracious Builder Scheme.