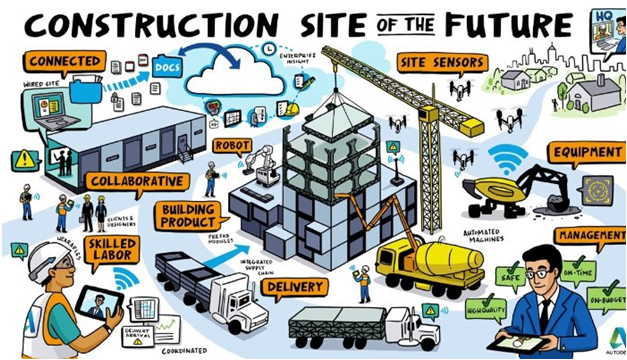

Technologies that are Shaping the Future of the Construction Site

Article and infographic contributed by Autodesk.

Article and infographic contributed by Autodesk.

Technology is dramatically transforming the construction industry, with professional-grade wearables and new survey methodologies, making construction sites safer and even accessible from remote locations.

Here’s a quick look at three technological breakthroughs that you may see on construction sites in the near future.

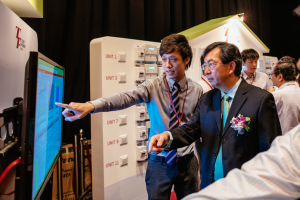

1. A smart badge that provides a real time view of the construction site

Workers can use the call button on the B3 Badge to request for help in emergency situations. (Image Credit: Redpoint Smart Badge and Asset Tags)

Imagine sitting a few hundred kilometres away from the construction site and having detailed visibility into workforce activity. Innovations like Redpoint Positioning’s compact and wearable B3 Workforce Safety Badge makes this possible.

This badge is equipped with an Indoor GPS platform that allows contractors to view and record workforce activities from remote locations. As an early Autodesk Forge partner, Redpoint Positioning leverages the Forge Platform’s APIs to monitor and record real time job site activities directly within BIM 360. Contractors can use this real time data to alert workers with a loud alarm if they enter danger zones or areas with electrical hazards.

The DAQRI smart helmet’s anti-reflective, scratch resistant face shield replaces safety glasses, and workers can use in-built USB ports to power additional equipment like flashlights. (Image Credit: DAQRI Products)

2. Smart helmets that provide in-depth information on construction sites

Hard hats and safety glasses are essential on construction sites, but they aren’t exactly high-tech. DAQRI, an LA based AR company has designed an “Industrial Augmented Reality (AR) Helmet” that features thermal imaging, head tracking, motion sensing, pattern recognition and much more. In contrast to an ordinary hard hat, the DAQRI helmet does much more than just protecting your head. Its in-built cameras and sensors provide workers with detailed real-time information about their surroundings. For instance, when a worker glances at a pressure gauge, the helmet can alert him if it displays a reading outside the expected range. Overheated panels and instruments can also be easily detected by thermal imaging tools and sensors, thus helping prevent accidents on the construction site.

3. Getting a bird’s eye view of projects with drones

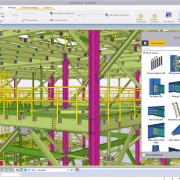

Some contractors are already piloting drones to conduct site surveys, but what’s even more exciting is the potential to turn the footage captured by these unmanned aerial vehicles into actionable and relevant intelligence for businesses.

Contractors can use this Dashboard to view real time updates captured by the EVO3, hence getting a glimpse of work that’s ahead, on time or behind schedule. (Image Credit: Skycatch)

Skycatch’s EVO3, for example, not only takes off and lands on its own, but also provides workers with a Dashboard interface to overlay aerial footage over construction plans and detect changes in progress, all from the sky and in real-time. Don’t want to invest in buying your own fleet? SkyCatch is also bringing the “sharing economy” ethos to drones with a new service called Workmode that helps companies find and hire unmanned aerial vehicles for mapping jobs, surveying, and other work.

Less Dust, More Data

From drones to sensors and every gadget in between, it’s plain to see why construction sites across the world are focusing on technology. While contractors are unlikely to go hi-tech overnight, the benefits of capturing data and leveraging it for greater planning and worker safety are simply undeniable.