Deckshield takes Galaxy Macau to greater heights

Phase 2 of mega casino Galaxy Macau’s development plan included the creation of a high performance car parking facility, ensuring that visitors to the resort would drive into a clean, quiet and visually appealing environment. The HK16 billion-construction project would see Macau’s new venue expand by 450,000 sq metres, with 3,600 hotel rooms and 500 more tables in the casino. This growth would see Galaxy Macau significantly increase both its footprint and customer volume.

To accommodate this expansion, a multi-storey car park that would reflect the site’s high standards of customer satisfaction, aesthetics and functionality was required. The resort knew that this was essential in order to provide a high quality visitor experience and to avoid delays, traffic congestion and failures from over-capacity and over-use.

Over 50,000 sq metres of high performance flooring materials was required to create the desired finish.

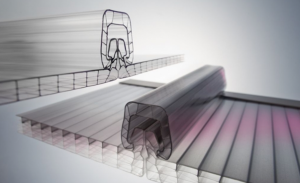

Thanks to the success of Flowcrete Hong Kong’s work supplying floors for Phase 1 of the project, the casino’s operators once again turned to the resin flooring specialists to provide a high performance, reliable and long-lasting surface for its upgraded car parking structure. Over 50,000 sq metres of high performance flooring materials was required to create the desired finish. The main floor area was coated over a nine-month period using 20,000 sq metres of the flexible, polyurethane deck coating system Deckshield ID as well as 14,500 sq metres of Deckshield LBD, which has been designed to act as a barrier to protect against moisture rising from the substrate.

Deckshield ID has been specifically formulated to optimise the floor area within large, multi-storey car parks. Deckshield ID is exceptionally robust, which means that it can withstand heavy vehicles constantly moving in tight circles. The chemically resistant nature of Deckshield ID also prevents exposure to automotive fuels and oils from deteriorating the finish. To ensure that the car park is a quiet and calm environment, Deckshield ID’s texture has been designed to reduce unpleasant tyre squeals.

Galaxy Macau chose a sleek, modern grey colour for the floor finish, which not only created a contemporary aesthetic but it would also provide an effective backdrop for the bright yellow signage and demarcation. Underneath the finish, 10,000 sq metres of both Isocrete K-Screed and the damp proof membrane system, Isocrete M-Bond Extra, was applied to ensure that the floor build up was robust and that the finish would be protected from moisture rising out of the substrate.

2,300 sq metres of Deckshield IDSD High Grade was used on the multi-storey facilities ramp while 10,000 sq metres of Flowcoat SF41 3mm Composite was applied in the loading bay and back of house areas.

During Phase 1 of Galaxy Macau’s construction, which was completed in 2010, Flowcrete Hong Kong supplied 15,000 sq metres of Deckshield in the initial car park and 18,000 sq metres of Isocrete K-Screed in the casino’s basement floor.

General Manager of Flowcrete Asia, Francis Tang, said, “It is imperative that the building materials specified for a location such as Galaxy Macau live up to the high standards of the venue. For our work during both phases one and two of the casino’s development, this meant providing the required functionality to support the operations of such a large, complex site while also ensuring that the environment constantly conveys a clean, visually appealing image.”

He added, “The expertise and experience at Flowcrete Hong Kong combined with our high quality flooring materials meant that we were ideally positioned to meet Galaxy Macau’s needs. We are committed to working closely with the resort as it develops and grows over the coming years.”