Posts

BIM for Construction is the future

/in News/by Editorial StaffThis article was published on Mar 2014 in Building Review Journal Vol 29 No. 2.

Text by Delene Lee, Images by Tekla.

Over the past 5 years, Asia Pacific has become the largest market for the concrete and cement industry, accounting for 58.1% of the global market. Developing economies in the region, especially China, India and Indonesia, are expected to support the expansion of the concrete and cement markets, due to the rapid development of infrastructure and an increase in residential construction.

With such a large and competitive market, contractors and engineers are on a never-ending quest to save time, reduce waste, and ultimately cut down costs.

How can BIM help these companies to reach those goals?

Today, architects and builders are increasingly embracing the benefits of BIM. The days of old-fashioned computer-aided design (CAD) and marked-up drawings are numbered. The future of construction is with BIM.

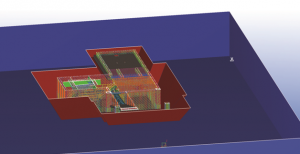

Unlike plain-vanilla CAD, BIM software creates a three-dimensional (3D) model full of smart objects embedded with information. BIM makes it easier to integrate architecture with engineering work, avoid “clashes” of building elements, instantly output lists of materials and labour, and automate valuable tasks like simulating the effects of sunlight in an interior space. With such details, BIM ultimately cuts down on rework and errors on site, leading to lower costs.

In a recent exclusive interview with Mr. Andy Dickey, he shed some light on how BIM helps the various stakeholders in the construction value chain and justifies the common barriers of adopting BIM. He also shares about a BIM software that one can download and use for coordination and communication on a project – for free, which is great for those who have yet to experience what BIM has to offer.

Andy is currently the CIP Concrete Business Development Manager for Tekla, a Trimble Company, based in Espoo, Finland. With extensive experience in the cast-in-place concrete industry, he now focuses on delivering BIM (Building Information Modeling) solutions for use in all phases of CIP Concrete Construction to Tekla Corporation customers worldwide.

BRJ: Who should adopt BIM Technology?

AD: We have quite a lot of stakeholders in the construction industry, but it is mainly these four categories of people: architects, engineers, contractors and owners (A,E,C,O). Tekla is particularly focused on engineers and construction professionals.

BRJ: What are the benefits that BIM deliver at every stage of the construction process?

AD: I think one of the biggest problems over the years has been productivity. One of the leading causes for that is really bad information… also known as drawings. So, BIM is a vehicle for a superior way to communicate amongst all the projects stakeholders; as communication and information can really affect productivity greatly. Particularly important in a market like Singapore, similar to the States, which has quite a lot of international workers in the construction field, and 3D is really a superior way to communicate with people that speak different languages.

BRJ: How can BIM make an impact in the Asia Pacific construction sector?

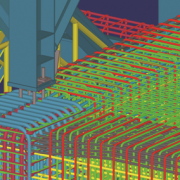

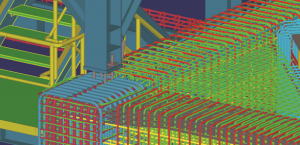

AD: One of the most prevalent forms of construction in Asia Pacific is reinforced concrete. Tekla is quite strong in providing BIM tools in this area. It is traditionally something that is very difficult to coordinate between various disciplines like mechanical electrical plumbing, fire protection, including all the reinforcing. As that part of BIM is growing, I think that particularly helps the Asia Pacific region because the reinforced concrete material type is so prominent.

BRJ: How is Tekla’s BIM solution different from its competitors’?

AD: I would say the primary difference is the fact that we offer solutions end to end. What you tend to see are tools that focuses on either design or pre-construction, or construction. But, Tekla is really in the verticals that we occupy – which is structural steel, precast concrete, reinforced concrete, we offer the solution end to end.

One of the reasons why productivity is so bad is because you are passing drawings downstream at every one of those stages that I’ve mentioned – from design all the way to construction. With Tekla, you can pass a model, so you don’t have this loss of information. You are not passing bad information from one stage to the next; you are passing really good information in Tekla, all the way through the process. That is what makes us different. We can tie the process together end to end, digitally.

BRJ: Does it require the all the various stakeholders to be trained in BIM technology to be able to work cohesively on a project?

AD: Yes, but the training you receive as construction engineers is quite different from a site supervisor, so it really needs to be tailored to the way in which they are using the software. And that is one of the things that we did. Engineers are learning about our analysis in design capability, while the site supervisors are probably not – they are just learning how to pull out quantities for how much concrete they need to order.

We configure different interfaces to match different needs of the various stakeholders – such that they don’t see certain buttons that they don’t need. It avoids confusion. The training is compartmentalised as well and that really helps make it easy. Even if they are just using models in a basic way, they can still work effectively.

BRJ: There are costs and required BIM-related training involved that can deter some companies from going forth to adopt this technology. What advice would you give to them?

AD: That’s a challenge in many markets and capital expenditure is always a concern, especially what we have been through the last few years of the economy slowing down. Now, with the economy speeding up, it has a new set of challenges – cash flow is an issue. They have to know that the return on investment (ROI) is definitely there. And it is a very quick ROI. If they don’t allocate the capital expenditure, they put themselves at risk going forward, as their competitors are doing that and significantly lowering their costs.

The cost of the software is actually the lowest amount of money that they are going to spend. Companies spend the most of their money on the people; training employees (which extends beyond BIM-related training), paying their hours etc. Hence, a small investment tool like Tekla is a small price to pay to magnify the productivity of the human capital. It can really multiply the effectiveness of that person.

BRJ: You mentioned a very quick ROI…do you have any examples to justify how long the payback is, in financial terms?

AD: We don’t reveal those statistics as it is difficult to be really specific about it. However, based on the feedbacks from our customers, they are telling us that it is very quick. You could check out some of our case studies, it is very detailed on what they did and how they implemented the software as well.

(Editor’s note: Those case studies found on http://www.Tekla.com/references)

BRJ: Is BIM technology appropriate for retrofit projects?

AD: Definitely! It is appropriate for renovations, retrofits, and additions. Tekla is a trimble company, which does so many things. But one worth noting is the positioning technologies. You could actually find out the position of the existing structure or elements and bring that information back into Tekla. The result of that is one of two things – with the total station you get the centre points and with the laser scanner you get a 3D model. You can bring either one of that into the Tekla environment and model the new stuff relative to where the old stuff is.

We get a lot of feedback – we have a case study coming out later in the year, a customer in the States, doing a project on a senior-living facility. They built drawings instead of using the drawings that they got from the City. Those drawings didn’t match where the existing building was supposed to be. But they were able to use the tools to properly locate it and accuracy became a non-issue.

BRJ: Are there any current key events or factors that would drive the adoption of BIM technology in the Asia Pacific region?

AD: They are the ones that I have already mentioned – communicating across quality information, overcoming language barriers, and productivity. Productivity is always a concern. Especially when you have hyper-growth rates that you see in some of the markets in Asia Pacific, it is a way to better manage that growth with a limited supply of resources. In some markets, labour is cheaper than the others, but good labour is always a limited supply at any price. The models can really enable quality work at almost any experienced level.

BRJ: What are your thoughts on future technology and trends predicted with BIM?

AD: It is all up from here – BIM for construction is probably the biggest growth area – particularly, in the area of connecting from design and detailing to the construction site.

A lot of what the designers BIM would be conceptual, because it’s to the level of detail that they need. But with Tekla, you get all the construction level of detail – every piece of reinforcing bar, cast, and all other tiny details on a project wide basis. You end up with a really detailed model but having the tools to make sure it really happens that way in reality – connecting the reinforcing bar information in the model to the machine that makes it, or connecting the position of things in the model to the robotic total station out on the site –that’s the next big thing and that’s the area that we are really strong in and heavily investing in.

BRJ: Is BIM stable at the moment or is it still developing?

AD: Its stable, but whenever you develop something, people want more. We see all sorts of ways to improve all the time as we engage with our customers. They provide us the shining light to see where to go to next.

BRJ: Do you have anything else you would like to share?

AD: Tekla has two main product lines – Tekla Structures it’s a tool you pay if you are in any of those interest groups that we were discussing, we also have Tekla BIMsight which is a free BIM tool that anybody can download and use and it’s a professional grade and I would recommend for anybody to download it and try it out.

BRJ: How long is it free for?

AD: Forever! Doesn’t mean it won’t change (eg. adding things to it). Our intention is to keep it free. It is a coordination tool, you can mark up, and it comes with a sample project. I really strongly encourage it to those interested in BIM and who doesn’t want to run out and spend a whole lot of money tomorrow or maybe next week right? (laughs)

BRJ: So then people won’t have to purchase BIM software anymore?

AD: Well…it addresses a few workflows, but you cannot make models with it. It is just to give people a taste on what they can do and what to expect. If they are already heavily involved in BIM, it is also a tool they can use for coordination and communicating on a project. The website is Teklabimsight.com, if anyone wants to check that out!

AD: Another thing I would like to add is that continuing to work in 2D drawings is the root cause of the lack of productivity. We really won’t see the productivity curving up until we move away from drawings as being is the only source of information on the project.

Experience 3D Printing

/in Technology & Softwares/by Editorial StaffIdo Eylon is the General Manager of Asia South, Stratasys Inc., he is responsible for the overall operation of the business while ensuring sustainable growth of the 3D printing business across Australia, Southeast Asia and India.

Ido started his career at Stratasys as an Applications Engineer in the company’s headquarters in Rehovot, Israel. He has gained extensive experience with the company’s technology and its applications across various industries and has collaborated with many of Stratasys’ customers from diverse trades. Ido has also assisted in a variety of projects to further expand and implement the applications and use of Stratasys products in numerous areas. By taking part in these activities, Ido contributed to discovering new and innovative solutions for Stratasys products. He has also been invited to speak at many events to spread and share his in-depth experiences.

Ido holds a Biomedical Engineering degree in Ben Gurion University.

At a recent launch of Stratasys’ new 3D Printing Experience Centre, Building Review Journal had an exclusive interview with Ido, to share more about how 3D printing can impact the architecture industry.

Ido Eylon

General Manager,

Asia South Stratasys AP Ltd.

BRJ: How have Stratasys’ customers in the architecture industry in the region and other parts of the world benefited from 3D printing?

Ido Eylon: Architectural bureaus can save a significant amount of time because 3D printers can achieve the characteristics of a model much faster, especially when complex geometries are in question. Architects can also easily validate designs and make good decisions earlier before committing to a final model because of the product realism. With the latest Connex3 released earlier this year, Architectural bureaus benefit from color printing and more productive and efficient printing processes with three different base materials ready-to-print on a single job.

The following are case studies that showcase the value of 3D printing to the architecture industry:

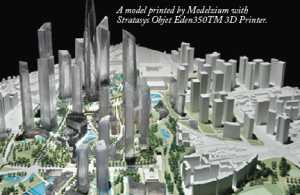

1) Seoul, Korea: Modelzium Architectural Modeling Firm Enhances Competitiveness with Objet 3D Printer Modelzium purchased the Stratasys Objet Eden350TM 3D Printer and were impressed by the fine details and smooth surface finish of the printed models. Compared to the previous CNC and manual method, by using 3D printing technology model turnaround time has been reduced by 30 percent for simpler designs and 50 percent for more complex designs. Another benefit Modelzium mentioned was that by using 3D printers to produce architectural models, they were able to cut production cost by 30 to 50 percent.

2) Toronto, Canada: McCann Architecture Architectural Modeling Firm Builds Scale Model of

Stunning Abu Dhabi Edifice with 3D Printing. Peter McCann Architectural Models Inc. (PMAMI) uses Stratasys 3D printers in order to be able to provide their customers the best architectural models possible. One of their clients was Chicago-based Smith+Gill Architects for whom they created a large model of Masdar Headquarters, the world’s first large-scale positive-energy building that generates more energy than it consumes. Stratasys 3D printers helped Smith+Gill to print a model that included multiple helix-shapes that needed to be both precise and strong because they were structural. Without the printer it would not have been possible for them to build the free-flowing roof for the Masdar HG model.

A model of Masdar Headquarters printed by Smith+Gill Architects using Stratasys 3D printing technology.

BRJ: What is Stratasys’ vision for the new Demo Centre in Singapore and the value it brings to customers/prospects in the region?

Ido Eylon: As a leading 3D printing industry player, Stratasys recognises the importance of implementing a global strategy in local context. Establishing a 3D Printing Experience Centre in Singapore allows our customers to see our innovative technologies in action and realise the values and advantages of 3D printing technology. A local demo center allows us to provide local support and offer accessible 3D printing solutions to serve the growing needs in South Asia and Pacific region. The establishment is also well aligned with our corporate vision to make 3D printing more accessible and to help customers revolutionise their product design and manufacturing processes. The demo center showcases the full technology portfolio ranging from desktop 3D printers to large, advanced 3D production systems, thus enabling designers and engineers to create models and prototypes for new product design and testing and to build finished goods in low volume.

While Asia-Pacific is the fastest growth engine of the Stratasys, contributing 21% of the company’s revenue (as at Q2 2014), Stratasys is committed to continuing its investment in the region to sustain the momentum.

The company has over 2,500 employees globally with approx. 200 based in Asia. Stratasys has a strong local presence in Asia with 8 offices in the region. Stratasys is confident about the future growth of the 3D printing market in Asia and continues to invest in strengthening its sales, marketing and channel infrastructure in the region and globally.

BRJ: What materials can 3D printing produce?

Ido Eylon: Stratasys offers a range of additive manufacturing materials, including clear, rubberlike and biocompatible photopolymers, and tough high-performance thermoplastics. This variety lets users maximize the benefits of 3D printing throughout their product-development cycle.

Two leading 3D printing technologies including:

Fused Deposition Modeling (FDM) Technology works with production-grade thermoplastics to build tough, durable parts that are accurate, repeatable and stable over time.

PolyJet Photopolymers offer fine detail along with final-product realism surpassing all other 3D printing technologies. They exhibit a chameleon-like ability to simulate clear, flexible and rigid materials and engineering plastics — and even combine many colors and material properties into one model.

BRJ: Stratasys recently launched a new product, can you share more about that?

Ido Eylon: Yes. In February this year, Stratasys launched the latest printer, the Objet500 Connex3 printer which enables an incomparable product realism and enhanced functionality with the revolutionary three-base-material capability.

The printer features a unique triple-jetting technology that combines droplets of three base materials to produce parts with virtually unlimited combinations of rigid, flexible, and transparent color materials as well as color digital materials – all in a single print run.

The Objet500 Connex3 lets users build rigid, rubber-like and clear parts into one model and offers hundreds of composite materials, blended right in the 3D printer. There are three color base materials – VeroCyan, VeroMagenta and VeroYellow – which are combined to produce hundreds of vivid colours. It eliminates secondary operations, such as assembly and painting. And when combined with Stratasys’ extensive range of PolyJet photopolymer materials including digital materials, rigid, rubber-like, transparent, and high temperature materials, Connex3 helps users to produce prototypes which simulate standard and high temperature engineering plastics.

Connex3 can simultaneously build as many as 46 hues/ material characteristics into an individual part, assembly or multi-part job in a single process.

BRJ: How is 3D printing different from the traditional modelling methods?

Ido Eylon: 3D printing is complementary to traditional manufacturing methods and benefits the users in many ways such as:

Shorter Time-to-Market: Users can print an assembled part without assembly or painting which is a significant time-saver. It helps architectural bureaus to validate designs and make good decisions earlier before committing to building.

Minimize costs-of-errors: prototypes can be created in a cost-effectively manner, allowing design reiterations prior to project initiation.

Confidentiality: Having an in-house 3D printing system would minimize the risk of design leakage.

Liberate Creativity: The ability to print complex geometries, and even more so with three different base materials simultaneously expands both the number of materials available and the number of combinations in an individual part. With a wide range of advanced material option and dozens of composites, user’s designs will come to life as realistic models, with materials characteristics like colours, rubber-like and transparency, earlier in the design process.

Optimized model development process: Stratasys printers enable to print out models that look like the final building. Fine feature quality provides high detail and smooth surfaces to create brilliant, precise 3D models. The product realism enables designers to build models with final product quality, not only to impress the audience in a pitch, it also helps to eliminate costly design errors at early stage of the model development process.

Be a step ahead with superior energy efficient solutions

/in Product, Sustainability/by Editorial StaffBuildings are valuable assets but the costs of maintenance can affect the bottom line of a business. As energy

costs continue to rise, building owners and facility managers face increasing pressure to reduce operational

costs, at the same time, increase productivity, improve sustainability and ensure business continuity for their

organizations.

A building’s chiller plants typically consume the most energy, so it makes sense that any strategy to reduce costs and to be environmentally friendly needs to start here. Johnson Controls is a global multi-industrial company with established core businesses in the building and automotive industries. It leverages on decades of YORK chiller innovations to deliver more efficient and sustainable chiller solutions in its continual push of the boundaries of chiller technology.

Larry Kouma

Product Management Director,

Asia Chiller Solutions, Johnson Controls Inc.

With over 20 years of experience in the HVAC industry, Larry boasts

vast technical knowledge in the design and application of steam and

chilled water systems. He is passionate about driving sustainability

across the value chain and has spent over a decade working with

energy efficiency standards. In addition, he has served on the

ASHRAE-ANSI 90.1 Standard Committee for 8 years.

In a recent interview, Mr. Larry Kouma (Product Management Director) shared his insights into regional trends in Asia’s refrigerant industry and on how the YORK® Magnetic Centrifugal Chiller (YMC2) system addressed the most pressing concerns of facility owners and designers.

BRJ: What are the regional trends in the refrigerant industry in 2014?

LK: With the awareness of ozone depletion and commitment to the Montreal Protocol, major suppliers are responding to the phase out of hydrochlorofluorocarbons (HCFCs). However, meeting all the requirements of safety, reliability, efficiency, Ozone Depleting Potential (ODP) and Global Warming Potential (GWP) is a tall order. The refrigerant that best fulfils these requirements are the hydrofluorocarbons (HFC) for large HVAC equipment applications, and in certain applications, natural refrigerants including hydrocarbons, ammonia, and carbon dioxide (CO2), are also safely applied.

BRJ: In what direction would these trends change in the next few years?

LK: Increasingly, refrigerants are also assessed based on their Life Cycle Climate Performance (LCCP), which takes a holistic approach in estimating all warming impacts – both direct and indirect – over the lifetime of the refrigerant for specific applications. Research will continue to push forward to find or create refrigerants that best fulfil all the necessary criteria while minimizing climate impact. Meanwhile, HFCs look to be the mainstay with European Union F-Gas Regulation to mitigate its GWP by addressing the containment, use, recovery, reporting, labelling, training, certification and some market prohibitions. This will have implications especially for sectors with high leakage such as automotive and commercial refrigeration.

BRJ: What are some of the most pressing building and facility challenges faced in the industry today?

LK: Rising energy costs and the need to improve productivity and minimize downtime continue to be key challenges for building and facility managers today. In addition, there is growing interest in sustainability across the industry as organizations increasingly seek to incorporate it into business goals and culture.

With the increased focus on climate change globally, many countries are enacting legislation and providing

incentives to modernize and retrofit existing facilities. In fact, the recent 2013 Energy Efficiency Indicator (EEI)

study by Johnson Controls found that such government policies and programs were one of the key drivers for

Asia to adopt “greener” and more energy efficient HVAC equipment and solutions.

In Singapore, the government’s push to green 80 percent of all buildings by 2030, mean that building owners

and facility managers will increasingly look to proven and reliable HVAC and solutions to help them to achieve

their energy efficiency and green building targets in the next few years.

BRJ: How does YMC2 help address them?

LK: Johnson Controls is one of the first to apply the magnetic-bearing technology to chillers, originally in response to mission-critical needs of the navy. Subsequently, we then extended this technology to make it available to other sectors (including commercial) to help address the growing demands with energy consumption reductions and sustainability. The magnetic-bearings reduce friction and vibration, while eliminating the need for oil to lubricate the bearings – delivering energy-efficiency, high reliability and noise control as a result. It addresses these challenges through:

Improved Efficiency – YMC2 chillers is 10 percent more efficient than new conventional, variable-speed chillers. The magnetic-bearing technology eliminates mechanical-contact losses in the driveline. In addition, proven energy efficient YORK® features such as the OptiSpeed™ variable-speed drive and the optimized centrifugal compressor have been retained and improved on. The efficiency benefits can be greater than 30 percent when considering replacement of an older existing chiller at end of life.

Reduced Noise – The YMC2 chiller is quieter than any water-cooled centrifugal or screw chiller on the market. Driveline vibration is eliminated with the magnetic-bearing technology, while the YORK® OptiSound™ control further helps reduce noise. As a result, the YMC2 chiller operates at a maximum of 73 dBA at full-load standard conditions (The human ear would perceive the YMC² chiller only half as loud as other magnetic-bearing chillers).

High Reliability – The design of the YMC2 chiller has fewer moving parts, requires less servicing and has a longer motor life. This helps to increase reliability and reduce maintenance costs. The chiller’s permanent-magnet motor has an inherently longer life than traditional motors, and the OptiSpeed drive’s soft-start sequence helps to further extend motor life.

Better Sustainability – The YMC2 chiller uses refri-gerant HFC-134a which has zero ozone-depletion potential. Furthermore, it is designed with 57 percent less refrigerant-piping connections which drastically reduce the potential for direct global warming caused by refrigerant leakage potential. The 10 percent to 50 percent efficiency improvement also reduces indirect global warming caused by greenhouse-gas emissions generated by electric utilities. Indirect impact is typically more than 95 percent of the chiller contribution to environmental warming impact over the operating life of the chiller.

BRJ: What is the potential for adoption of the new YMC2 technology in Asia?

LK: We see lots of potential for adoption in both the developed and developing markets in Asia. Interest in the developed markets, such as Australia, Hong Kong and Singapore, would be more immediate and widespread. For one, the YMC2 chiller is ideal for retrofit installations because it not only delivers higher efficiency but also caters to a higher capacity within a small footprint.

We are also starting to see interest in developing markets, such as India and China, where a few forward thinking companies have started to implement high efficient systems and solutions. At the same time, the governments in these countries have increasingly taken steps to drive the adoption of more energy efficient and green solutions across businesses and infrastructure through regulations and incentives. So we can expect good growth in these markets in the coming years.

In general, YMC2 is a versatile solution that is suitable for application across a wide range of industries. Given its high reliability and superior sound control, it is also recommended for high performance facilities such as data centers, healthcare facilities, educational institutions and concert halls.

BRJ: In terms of cost savings, how long is the payback with YMC2 installed?

LK: Generally less than five years, and can be lower than three years depending on total system design and ambient conditions.

BRJ: Does YMC2 help existing buildings? Please elaborate.

LK: The YMC2 contributes towards helping reduce the energy consumption and operational costs of commercial and industrial buildings. It is also ideal for retrofit in existing buildings because of its small footprint – it can fit into the old chiller space and still cater to a higher capacity (up to 560TR) and deliver higher efficiency. Its energy efficient and sustainable features also help existing buildings meet the energy management and environmental targets set out by building owners and increasingly, governments.

In Singapore, government legislation and incentives play a big part in driving the adoption of more energy efficient HVAC solutions. This is in part due to the Government’s push to green 80 percent of all buildings by 2030.

New regulations increasingly require new and existing buildings to achieve a minimum Green Mark standard when retrofitting or installing a new cooling system. Existing buildings are also required to carry out regular energy audits and report annual energy consumption data.

Johnson Controls, has helped existing buildings such as PoMo, a mixed-use retail facility achieve the BCA Green Mark Platinum rating with YMC2. The YMC2 helped address the needs of the building owners by reducing energy consumption and controlling excessive equipment noise. With the YMC2, the retrofitted chiller plant achieved an impressive system efficiency of 0.65 kW/RT and successfully lowered sound levels below 73 dBA.