Unique Roof Creates Thailand’s Largest Column-Free Exhibition Space

The Bangkok International Trade & Exhibition Centre (BITEC).

The Bangkok International Trade & Exhibition Centre (BITEC) now has so much open space that exhibitors have the capability to stage displays reaching 25 m into the air. Exhibitors and visitors to the newly expanded exhibition centre will benefit from unblocked views and an innovative roof which is capable of accommodating huge suspended displays. The BITEC now has so much open space that were it to stage an aviation show, Airbus would be able to showcase a full-sized A380 model indoors.

In line with the vision of its owner, BHIRAJ BURI Co., Ltd, the new BITEC heralds an era of unrivalled exhibitions and related events in Bangkok. The exhibition centre opened in 1997 and is located in the Bang Na district of the city.

As the lead structural engineer, Aurecon office in Thailand played a key role in the expansion project. The company worked closely with the architect to balance aesthetics and engineering practicalities, optimising the design while also respecting the architect’s desire for a dramatic addition to the Bangkok skyline – complete with elegant masts and cables. In addition to the detailed design of the finished structure, the company worked out a detailed construction sequence to facilitate the erection of this unusual structure for the main contractor, Italian-Thai Development.

Creating Space and Width

Stretching to 108 m between columns at its widest section, the new long-span structure gives the venue its impressive floor space possibilities. The expansion more than doubles the area of the exhibition centre, adding 40,000 square metres to the existing 35,000 square metres.

The expansion has two distinct, large areas, each with a different clear height. The first section features a height of 25 metres – high enough to accommodate the tail section of an Airbus A380 replica – with a 108-metre column-to-column span; while the second has a clear height of 15 metres with a 90-metre column-to-column span. The light-weight roof also has the capacity to support large hanging loads.

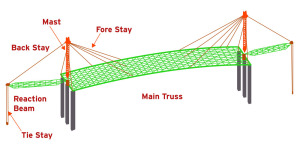

Illustration 1.

One of the biggest challenges for the design was supporting the weight of the roof. To counter this, Aurecon’s engineers used advanced modelling and structural analysis to evaluate the size, specification and siting of the cable-stays, together with the optimum lattice design for the roof truss.

To create such long column-to-column spaces, Aurecon designed an innovative support system for the roof structure. This design has the main roof truss supported by fore stays on each side, with these cables then supported on masts around the edge of the building. A further cable from the top of each mast is anchored to the ground, via a configuration that incorporates a back stay, tie stay and reaction beam. There is one mast design for every three roof trusses (See Illustration 1).

Getting the Sequence Right

More importantly, a detailed erection sequence was developed for the building contractor, which required the roof’s lattice structure to be jacked above its final resting height during assembly. Doing this meant that as the contractor systematically removed the jacks – in line with the erection sequence – the downward motion induced the required tension in the cable stays to meet design requirements.

To create such long column-to-column spaces, Aurecon designed an innovative support system for the roof structure.

“One of the most significant engineering challenges was making sure we got the erection sequence right,” explained Pisit Yingmanokit, Technical Director, Aurecon in Thailand, the project’s senior structural engineer. “It was quite a meticulous process to ensure the roof would maintain its desired shape and strength, but the end result is something unique in Thailand, allowing the venue to stage much bigger and better events.”

“Aurecon is proud to have had the opportunity to collaborate with one of Thailand’s premier property developers to engineer the focal element of the BITEC expansion,” said Thiti Ariyakul, Project Leader and Executive Director of Aurecon in Thailand. “It is a perfect showcase for the design and engineering talent of Thailand, with every phase of the job handled by a Thai company.”

The new BITEC venue welcomed its first exhibition on 23 November 2016.